Msc. Mechanical Engineer Edgar Andrade Orellana

Technical Manager

eorellana@vibrotechnology.org

The pipelines of greatest importance for vibration analysis, stress, and fluid pulsation are the penstocks. These pipelines are subjected to pressures that could cause the pipe to crack or force wave vibrations due to their great length. The implementation of a reliable measurement process in the Structural Health Monitoring of pipelines is primarily based on fully dynamic methods. We must not overlook the interaction of the turbine runner

striking the incoming water, as many times as it has blades (blades, buckets, etc.), a vibration that could be high and capable of pulsatingly exciting the pipeline.

STRAIN GAGE

This device, used for a long time, remains one of the best devices for measuring absolute deformation. Depending on the structural element to be measured, such as a shaft, beam, column, plate, etc., and their combinations, we can quantify and qualify any force based on the number and position of the strain gages. In practice, flanges, bolts, and the welding of pipes in a hydroelectric power plant are measured to be verified for fatigue.

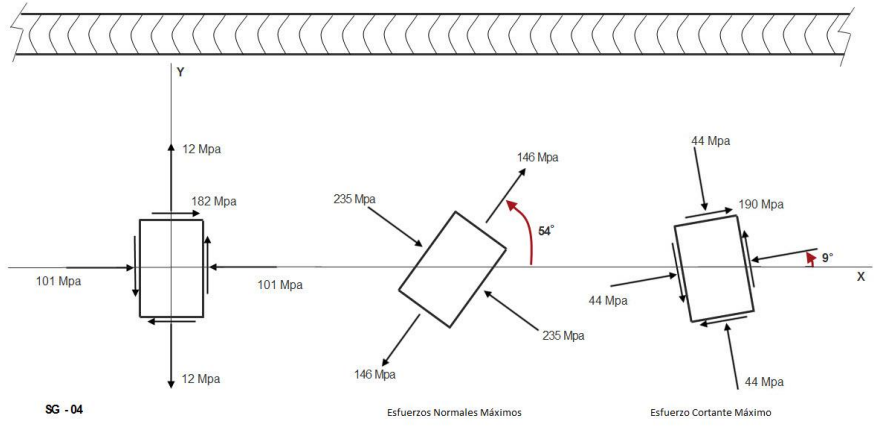

Stress verification in a 60″ Francis turbine penstock

Stress verification in pipe weld bead using rosette-type strain gage.

Result of maximum static stresses

Normalized energy of dynamic stress frequencies

HYDRAULIC PULSATIONS

The measurements on the external surface of the pipe respond to structural force responses such as forces from the fluid. In order to obtain clearer information, static and dynamic pressure in the fluid must be measured due to internal pressure changes, variations in pressure from water hammer, which are extremely fast-traveling, Karman vortices induced by design, and excitation due to changes in kinetic energy in the fluid

Dynamic pulsation sensor in turbine spiral casing and penstock.

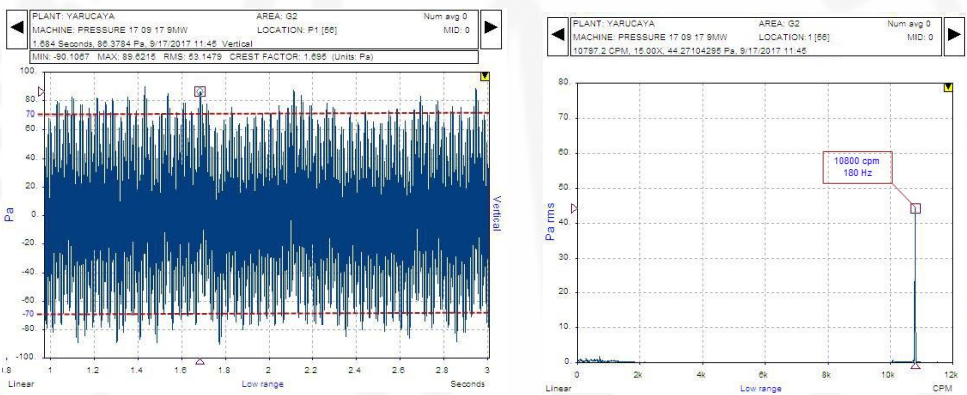

Fluid vibration measurements – hydraulic pulsation

Fluid vibration measurements – hydraulic pulsation cascade.

ABSOLUTE VIBRATIONS

Very commonly used methodology that helps us determine the severity in which the equipment is located, very useful to know which frequency predominates and could be the cause of the problem. It also shows us the time spectrum where we can see how it behaves and what is the direction or phase of the vibration module.

ADVANCED METHODOLOGIES

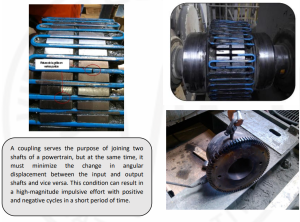

These are tests designed to complement or obtain relevant and necessary information about the analyzed equipment.