Msc. Mechanical Engineer Edgar Andrade Orellana

Technical Manager

eorellana@vibrotechnology.org

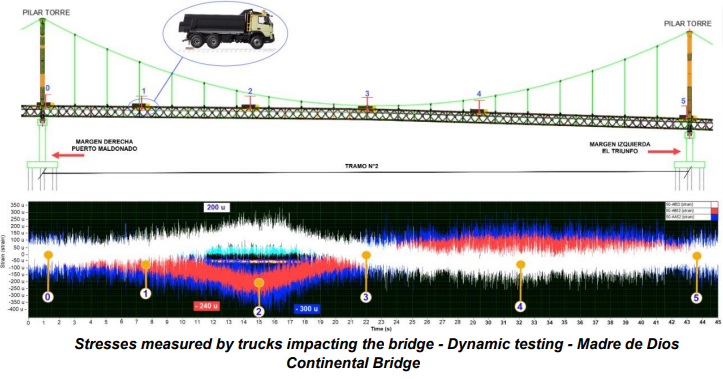

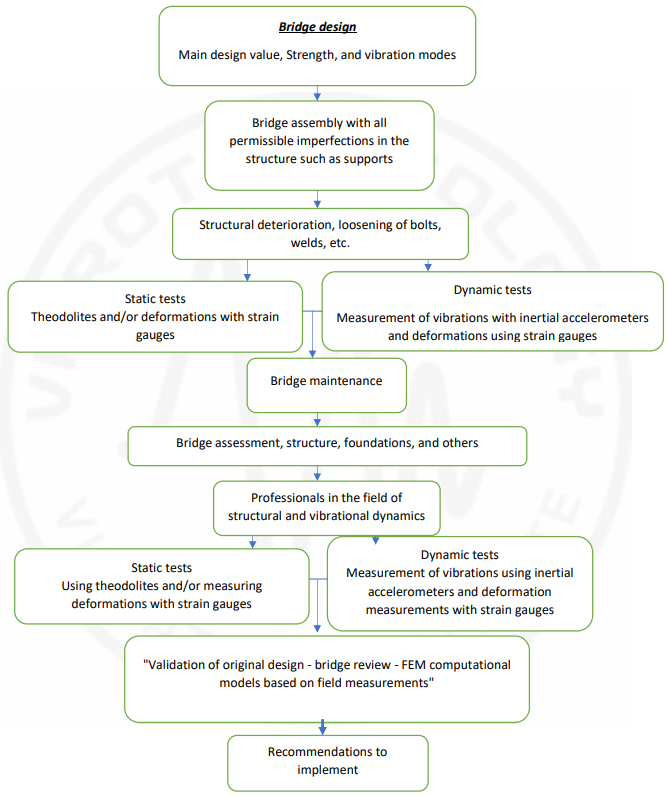

h this configuration being longer in length relative to their width. Bridges are always subjected to oscillating movements that the design accommodates. Therefore, bridges are calculated to comply with regulations and for strength.

In our country, the regulations include, among others, the static test, which involves attempting to achieve, using trucks, a dead load as a percentage of the design load.

Will static testing alone suffice?… No! That’s why dynamic testing is necessary, where the bridge’s response under real conditions it faces must be measured, such as temperature, winds, asymmetric loads, impacts, variable loads, etc.

What should we do? … Sequence of analysis

How we Measure?

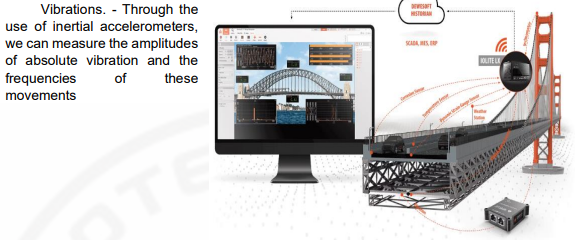

Installation of MEMS inertial accelerometers in bridges. * Courtesy of Dewesoft Slovenia

IOLITE STG – Strain gage in structure

Sensors MEMS – * Courtesy of Dewesoft Slovenia

Deformations and stresses. – By bonding strain gauges of the necessary type to the structure, we can determine the amount of stress, its direction, and the nature of the force to which the bridge is subjected.

«Strain gauge for tension on cable strands – Pizana Bridge»

Measurement of tension-induced deformations, causing linear stresses in cables and hangers, is crucial for verifying the structural health of bridges and for controlling the tensioning of these elements. The significance of this technique lies in its ability to synchronize and observe the interaction of tensions in various cables and/or hangers, enabling us to determine the static tensions present at each moment, as well as the fluctuating dynamic tensions.

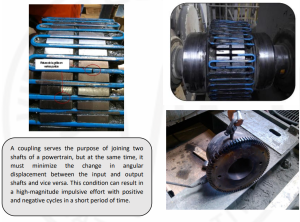

Impacts or impulsive phenomena, known as shocks, occur in transient processes or time intervals. Therefore, the use of strain gauges, properly installed, allows us to measure deformations, stresses, torques, etc. We can also identify maximum condition values, as well as the dynamic condition where forces can generate deformations and their directions. The implementation of a reliable process in «Deformation Monitoring» is primarily based on fully dynamic methods. Hence the question: How can a quasi-static structure, shaft, etc., be affected by exciting sources? And how much?

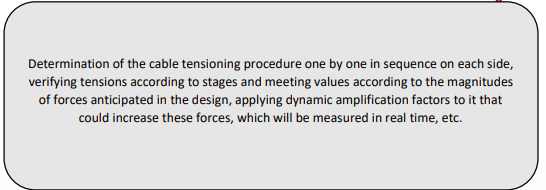

In the case of cable tensioning procedures in bridges, it is essential to verify the tension sequence in each cable and central hanger or hangers. This ensures that each time tension is applied mechanically, there is no appreciable deviation due to loosening, fissures, or improper loading. Therefore, dynamic deformation analysis is the least intrusive and highly accurate method for these procedures.

A flow of analysis and steps can be generated to assist in the logical, intuitive organization, and measurement lifting of STRAIN GAGES installed in each cable to be subjected to tension. It is important not to overlook the need for satisfactory know-how, expertise, and training of the personnel involved in post-analysis.

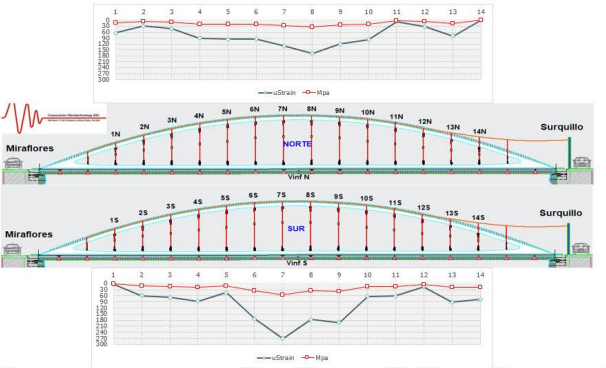

Tensioning of hangers and real-time verification in 16 hangers per side.

Punta Arenas – San Martín Bridge Peru

Measurement of tensions in the cables of the Junín de Paseo de la República Bridge Peru

Junín Bridge – Lima – Continuous real-time monitoring for 03 months

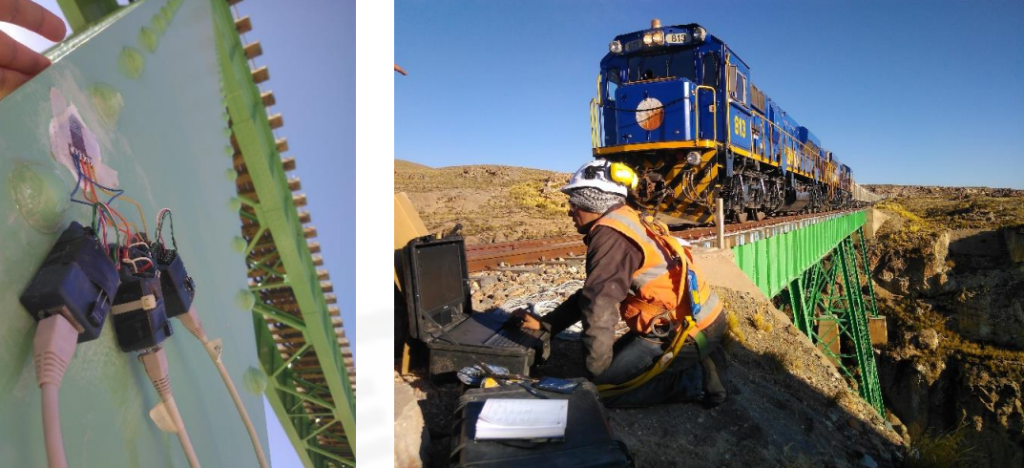

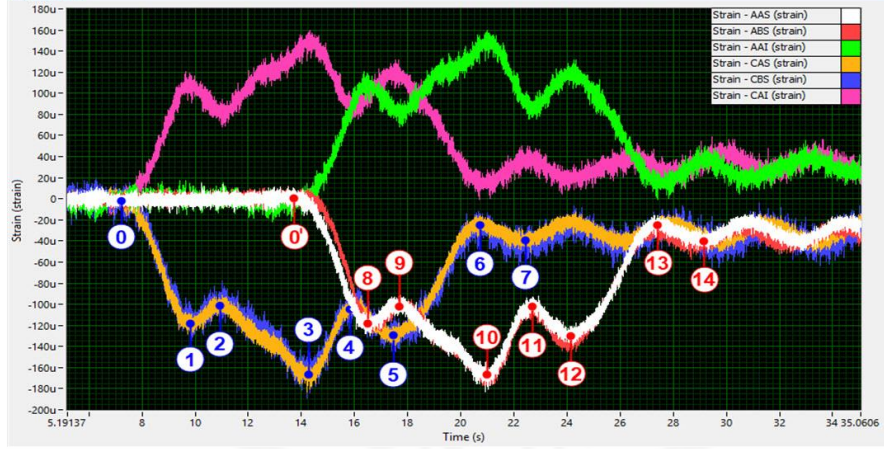

Sumbay Railway Bridge – Arequipa – Peru – Structural health due to increased frequency and load

Sumbay Railway Bridge – Arequipa – Measurement and installation of strain gauges.

Sumbay Railway Bridge – Arequipa – Measurement of deformation during train passage, observing variations in static conditions and dynamic deformation frequencies.