Msc. Mechanical Engineer Edgar Andrade Orellana

Technical Manager

eorellana@vibrotechnology.org

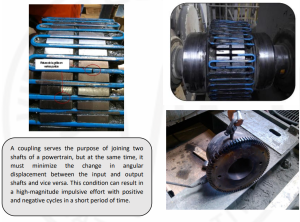

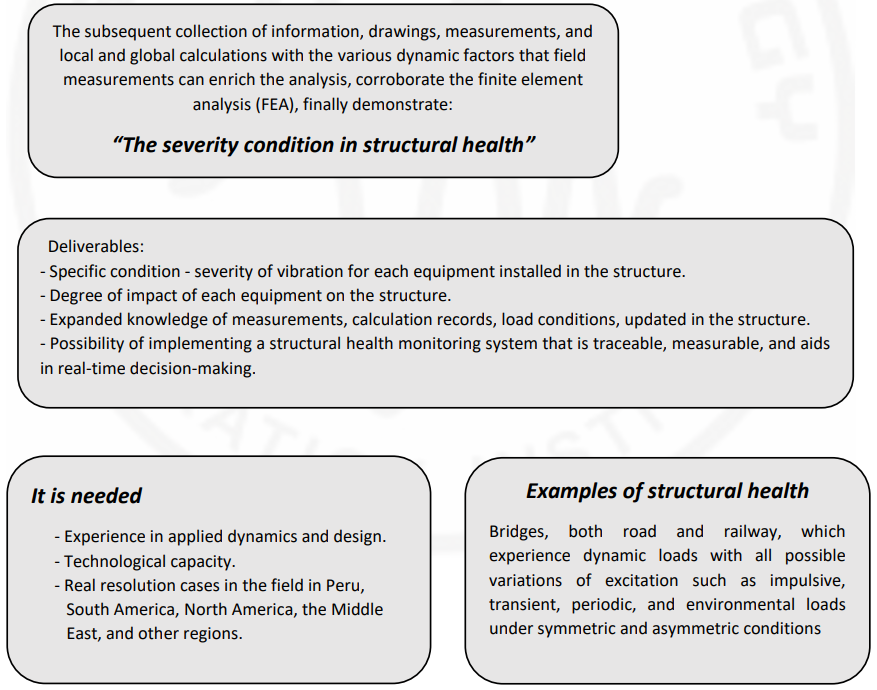

The implementation of a reliable process in «Structural Health Monitoring» is primarily based on fully dynamic methods. Hence the question arises: «How can a quasistatic structure be affected by excitatory sources?» and «To what extent?»

There is no single answer as there are several possible variables such as looseness, cracks, inadequate load designs, etc. Therefore, vibrational analysis becomes relevant in detecting damages or quantifying the severity of damages and aids in predicting remaining life.

A flow of analysis and steps can be generated to help in logical, intuitive organization, and measurement gathering (with accelerometers and strain gages) installed in strategic and appropriate locations. It’s important to emphasize that the knowhow, expertise, and training of the personnel involved in post-analysis must be satisfactory.

Overland conveyor belt of 5 kilometers

Reinforced concrete structure for mining crusher

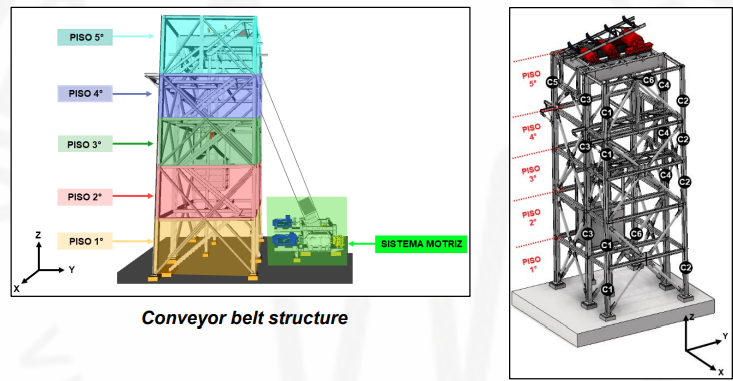

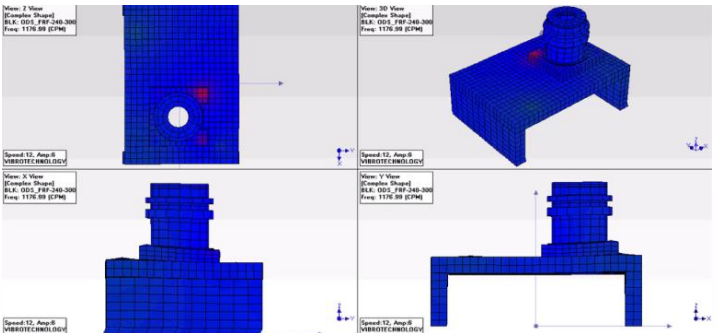

3D model for ODS (Operation Deflection Shape) analysis

Vibration measurements in concrete

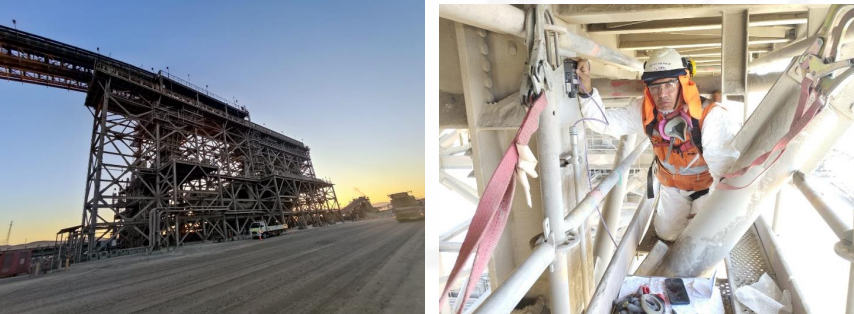

Vibration measurements in oxide building structure – Marcobre

Measurement of stresses in the cables of Junin Bridge on Paseo de la República Peru

Junin Bridge – Lima – Continuous real-time monitoring for 03 months

Strain gage for tension