(Por: Msc Ingeniero Mecánico Edgar Andrade Orellana)

eorellana@vibrotechnology.org

The implementation of monitoring sensors in a mining vehicle entails several additional considerations such as power source, space for measurement equipment, high temperatures for sensors, and installation and wiring of equipment. That’s why Vibrotechnology designs the type of measurement with multiple simultaneous channels and software according to the specific needs of each service. Vibrations that may be perceptible in any part of the unit must be analyzed following a criterion of searching for excitation frequencies with the highest amplitude. By installing low and high-frequency

accelerometers in strategic locations and properly configuring them, a broad spectrum of possibilities can be covered. Of course, it is essential to ensure that the know-how, expertise, and training of the personnel involved in post-analysis are satisfactory.

Caterpillar 793D mining truck

Caterpillar 793D engine

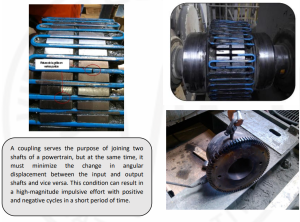

Caterpillar 793D mechanical powertrain

Caterpillar 793D chassis and cabin structure – Seat sensor

Vibration analysis on operating engine CAT 797F

Modal analysis of turbochargers (6), CAT 797F

Caterpillar MD6640 Drill